May 6, 2024

5 Reasons Your Bakery’s Tins & Trays Don’t Last as Long as They Should

Your bakery’s tins and trays are some of your company’s biggest workhorses. Because they’re constantly in use, they have the potential to accumulate wear and tear that can significantly reduce their lifespan and affect the quality of your products if damage points or improper handling procedures aren’t identified quickly.

Fortunately, you can take steps to prolong the life of your bakeware and keep your production moving. Whether you’re a seasoned bakery professional or new to the industry, understanding how to properly care for your bakeware is essential for maintaining efficiency, quality, and safety in your bakery operations.

5 Reasons Your Bakeware is Failing Prematurely

Material Damage

Material damage to industrial bakeware, especially in a busy bakery setting, can significantly affect longevity and performance.

One of the most common forms of material damage happens when tins and trays are mishandled, either manually or mechanically. In the fast-paced environment of an industrial bakery, it’s not uncommon for tins and trays to be dropped, banged against other tins, trays, and equipment, or stacked improperly. These actions can lead to dents, warps, and scratches on your bakeware. Such damage affects the bakeware’s performance and can influence baking results, from unevenly filled moulds and stuck-on product to tin and tray jams or stoppages on the production line.

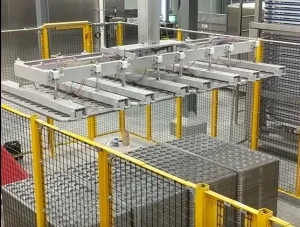

To prevent these negative results, it’s crucial to train staff on the proper handling and storage of bakeware. Implementing soft landing surfaces for manual or slam depanning practices, such as rubber mats or rubberized handling arms on automated handling systems, can mitigate the risk of such damages.

You can also calibrate stackers to minimize drop height and speed. In addition, look for ways to eliminate sharp edges, tight radius turns, or tins or trays rubbing on the sidewalls of conveyors. The consistent metal-on-metal contact of tins and trays with these points can damage and wear down the sides of the bakeware. Applying UHMW on these high-contact surfaces can help prevent this damage.

Another cause of material damage is leaving product debris on the bakeware, left by either dry or liquid toppings. Dry toppings can be pressed into the tins and trays when stacked, leaving behind particles that get stuck in the coating. Introducing moisture in any form to the bakeware, including the use of water splitting, protein glazes, or water-based products (including release agents) can decrease the life of bakeware and coatings. Ensuring that tins and trays are cleaned and recoated on a regular basis will help protect the metal substrate and prevent premature failure.

Improper Storage

The way tins and trays are stacked and stored can also inadvertently cause damage. Whenever possible, bakeware should be stored upside down in order to distribute the weight of the tins and trays on the rim, which is the strongest part. Avoid overstacking, as this can damage and deform the tins and trays at the bottom of the stack, making them unusable or making the stack unstable, causing a safety and storage hazard.

The way tins and trays are stacked and stored can also inadvertently cause damage. Whenever possible, bakeware should be stored upside down in order to distribute the weight of the tins and trays on the rim, which is the strongest part. Avoid overstacking, as this can damage and deform the tins and trays at the bottom of the stack, making them unusable or making the stack unstable, causing a safety and storage hazard.

To prevent such issues, make sure your bakery maintains bakeware storage areas in good condition, ensuring that the area is clean, dry, free of debris or sharp objects, and provides enough space for the recommended bakeware stack heights. If you are unsure of the recommended stack heights for your tins and trays, please contact your American Pan sales representative.

Improper Cleaning

For bakeries that manually clean tins and trays, harsh scouring pads, metal utensils, or abrasive cleaners can scratch and degrade the coating and material. These scratches can reduce overall performance, leading to a shorter lifespan for the bakeware and coating and potentially compromising food safety. Baked-on food particles left on tins and trays should also be avoided.

For bakeries that use in-line washing equipment, improper cleaning practices also include neglecting thorough drying and storage procedures post-wash. Moisture is a tin or tray’s adversary, particularly when they are stacked or stored without fully drying. This residual moisture can lead to corrosion on the bakeware, especially where the protective coating has been compromised.

To avoid this, ensure that tins and trays are thoroughly dried before placing into storage. Consider non-corrosive tin and tray band options such as aluminum or stainless steel if you are using in-line washing systems. Using gentle, bakery-approved detergents and ensuring bakeware is cleaned promptly after use will help maintain condition and functionality.

If using an in-line dry method for cleaning bakeware, avoid using abrasive brushes. Brushes used on cleaners should not be too stiff as they can scratch coatings. Air knives should be set at the proper pressure, as too high of a pressure can cause seeds or other particles to be blasted against the tins and trays and thus scratch the coating.

Inspection and Maintenance

The demand for continuous production can push equipment beyond its intended limits. Over time, tins and trays can lose their structural integrity, leading to warping or bending. This not only affects the uniformity and presentation of baked products but can also cause uneven baking.

To mitigate the risks associated with bakeware overuse, bakeries should adhere to manufacturer guidelines regarding their tins’ and trays’ lifespan and preventive maintenance. A regular inspection routine can help identify bakeware nearing the end of its useful life, allowing for timely refurbishment or replacement before significant problems arise. A regular bakeware service plan can help automate this process and ensure you’re staying on top of your bakeware needs.

Lack of Proper Coating Care

The absence of proper coating care or over-use of release agents on bakeware can significantly impact lifespan and the quality of the final baked goods.

Non-stick coatings are very effective for ensuring that products release easily from the tins and trays without sticking, tearing, or requiring excessive force, which can damage both the bakeware and the baked product. Over time, improper bakeware handling, cleaning, or other procedures can damage the coating and lead to increased sticking, which often results in bakeries applying more release agents to compensate.

This can not only affect the final characteristics of the baked good but also contribute to the degradation of the bakeware’s surface, as the buildup from these agents can require additional time and cost when cleaning tins and trays with an industrial service such as Pan Glo. For manual cleaning, abrasive methods may be required, which will further damage the bakeware.

To prevent these issues, it’s essential to regularly check bakeware coatings for signs of wear and tear and recoat as needed. Additionally, ensure that any release agents are properly utilized. For example, new tins and trays and freshly recoated bakeware will require less release agent than an aging one. The amount of release agent can be increased over time to accommodate as the coating gets older. By using this methodology, bakeries can save money on release agents and provide a cleaner, safer environment for their employees.

Take a Closer Look at Your Bakeware Lifecycle

Purchasing and maintaining industrial bakeware is a significant investment. Have you considered an analysis by an outside partner to help evaluate opportunities for efficiencies? How are you collecting and tracking data to make informed decisions on pan care?

At American Pan, we work directly with our customers to take a comprehensive look into your operations. Together, we outline areas where you could be saving time, energy, or money, and ways that can help you get the most out of your bakeware.

Find your local American Pan sales representative here to get started.